As an Amazon Associate I earn from qualifying purchases. Learn More.

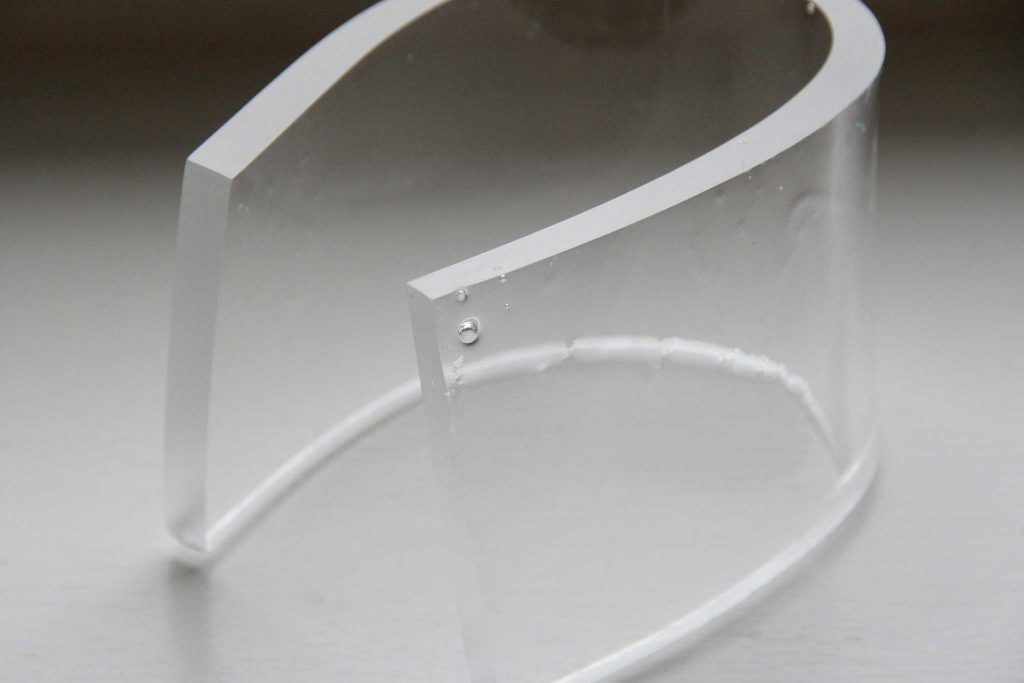

A transparent glass window looks classy at the office and at home. But it is always better and cost-effective to use plexiglass instead of glass that will give the exact look and view from any side.

We will emphasize on plexiglass in this article and will also let you know how to cut plexiglass with a table saw.

As an alternative to glass, nothing can beat the perfection of plexiglass. Moreover, it is inexpensive and the installation will give you no worry at all. Acrylic plastic has been used to form it that gives a proper transparent view.

But what about cutting plexiglass? Can you cut plexiglass with a table saw? As you have to make a number of pieces from a long sheet, cutting it is mandatory for any project. Though there are different types of glasses, you may face difficulties to cut for some types. But the answer is you can cut plexiglass with a quality table saw.

For getting the maximum from plexiglass, you have to find out a better way on how to cut plexiglass without cracking.

Table of Contents

What Is Plexiglass?

Plexiglass is also known as acrylic glass. It is actually a glass-like substance. It seems like acrylic sheeting but it is different product. This glass-like product is made with different types of UV, and coatings.

The versatility is one of the main reasons behind the popularity of plexiglass. You can use it for a variety of projects and it will work as like original glass. But to ensure good use, cutting it properly is very vital.

By using plexiglass, you can make tabletop, picture frame, window glass, and a variety of things, spending half or less than that comparing regular glass. As it is completely shatterproof, there is no way to underestimate this handy substitute.

Regular glass is costly and can be broken down anytime. To reduce the cost of your office decoration, interior or furniture, plexiglass can be the most perfect solution for you.

The Basics of Cutting Plexiglass

Though we are going to use a table saw, cutting wood and plexiglass are not the same. This is why a few additional tools are required making the cutting precise and accurate.

We mentioned before that, plexiglass is kind of a plastic (acrylic). So, a specially designed blade is the first thing that we need that can cut through easily. And it must be sharp enough.

Plexiglass is a kind of acrylic sheet but not all of them are similar. Some kind of them needs to be melted down before cutting. Acrylic sheets are found in 3 forms; below we will know about them:

- The cast acrylic

- The extruded acrylic

- The polycarbonate acrylic

Cast Acrylic: This type of sheet is the most common in the market and been largely used as plexiglass. Using a table saw, you can cut it easily as it is very hard to let the blade go through. But do not forget to use the accurate saw blade, otherwise, the cutting won’t be precise.

While this acrylic is the best kind and perfect as plexiglass, you have to spend a little more to cut it than other types.

Extruded Acrylic: The second type is the extruded acrylic sheets that are softer than cast acrylic. Also, the melting temperature is quite low for these. So, you are not allowed to use power tools to cut extruded acrylic sheets.

You may use a method, named ‘score and snap’ to cut the sheets. The beneficial factor of this sheet is that it can be easily molded. By applying the right amount of temperature, you can do it easily.

Polycarbonate Acrylic: This is the last kind of acrylic sheet and can be used for several purposes. Along with some extra precautions, the power tool is very handy for cutting it.

Polycarbonate acrylic is limper than plexiglass. So, it will be wise if you do some experiment to know how quickly the blade is working and how the moves should be made.

How to Cut Plexiglass with a Table Saw?

Though it is not tough to cut plexiglass with a table saw, some process needs to be followed properly. Here, we will discuss the process point by point to make it understandable to you.

1. Measuring the Plexiglass: Before cutting, you should use the tape measure to measure the plexiglass. If the glass is thin, you might face trouble while using table saw. In this case, a utility knife will work well.

To use the table saw, the minimum thickness of glass should be ¼ inch. In or above this value, any glass will be cut down easily.

2. Pick the Right Saw Blade: We have already gathered ideas about the types of plexiglasses. If it is soft, then the blade with fewer amounts of teeth will be perfect. It will create less friction than any other type of blade.

A saw blade with more teeth is useful for cutting harder plexiglasses. This type of blade will make less chipping than fewer teeth blade. The harder the glass is, the more teeth the blade requires.

3. Measuring the Cut Size: This is one of the most crucial parts before applying the table saw. You have to measure the right size and make a mark based on that. To hold the plexiglass perfectly, setting up the fence on the table is needed.

Besides the body, the edges should also receive a proper cut. Otherwise, a narrow portion can occur.

4. Wear Safety Glass: Wearing a safety glass will keep your eyes safe from small particles while cutting. So, it is mandatory to use safety glasses to protect your eyes.

5. The Cutting: When all the precautions have been taken and you have done all the pre-works, it is time to cut the plexiglass. Make sure that one-end has held up and turned on the saw.

Let the blade go through the marked area slowly. There is no need to apply extra pressure to make the cutting fast. Besides keeping your eyes on the blade, do not forget to look after your hand so that it cannot get close to the blade.

If melting occurs stop or go slow. You might have to change blades if necessary. There is nothing to be worried about it. If the edges are not plain, use grit sandpaper to make it fine.

Wrap Up

Plexiglass is a kind of plastic, not a glass. So, you should not apply the glass cutting method for it. If you have gone through this guide, then you now know well how to cut plexiglass with a table saw.

Using a table saw is not a difficult method. If you have one, follow the detailed process above and let us know how the cutting went.